The Most Common Industrial Applications for Bright Basic Wire

Learn more about the different applications of bright basic wire in various industries, including construction and manufacturing.

Learn more about the different applications of bright basic wire in various industries, including construction and manufacturing.

Bright basic wire shows up in countless industrial, construction, commercial, and agricultural applications. It’s produced by cold drawing steel through a die, which gives it the finish, tensile strength, flexibility, and ductility needed for these applications. It can also be welded, painted, powder coated, galvanized, or finished in other ways to improve performance.

In this blog, we’ll cover the many applications of bright basic wire and why industries rely on it.

Bright basic wire is made into construction products, such as nails, chain link fencing, and, in particular, wire mesh.

Wire mesh provides stiffening and reinforcement for concrete floors, helping them resist deformation and cracking under load. The load-bearing properties of wire mesh are set by the tensile strength of the wire and the mesh count (the primary measure of mesh density). Corrosion resistance is provided through a combination of the steel alloy selected and appropriate finishing processes, such as galvanizing.

Beyond wire mesh and other construction materials, bright basic wire is also used in roadways and bridge paving and can be found in all types of walls.

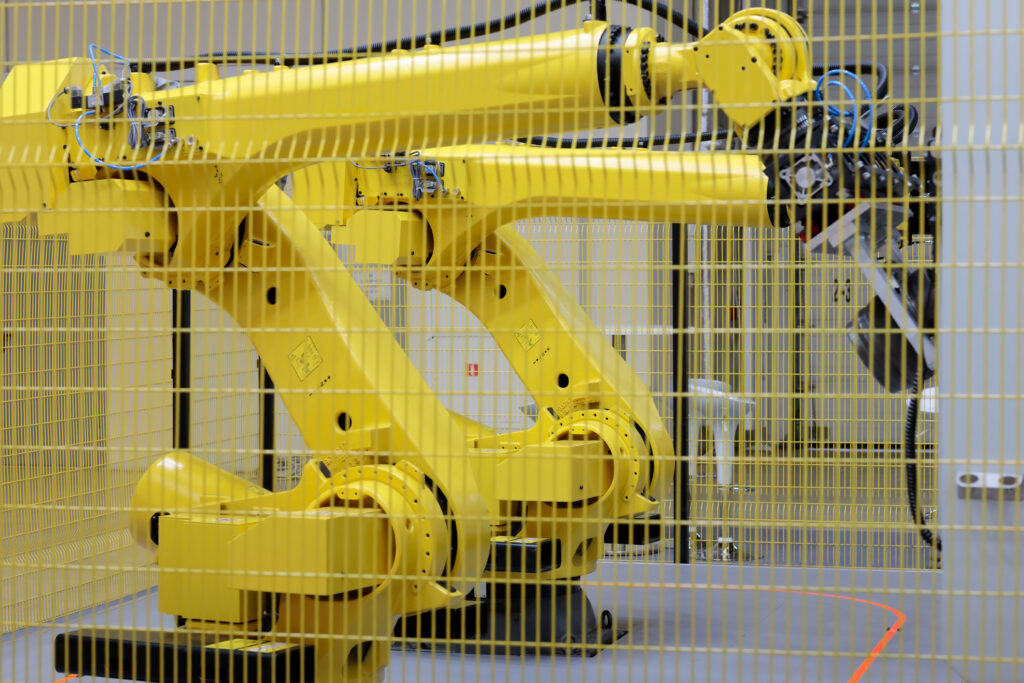

In manufacturing, bright basic wire often ends up in mesh baskets and guards.

Mesh baskets are used in processes like washing and plating, where they let fluid flow through and over any parts that are being treated. Mesh baskets can also be used for material storage and handling, and mesh is sometimes made into shelves, especially where airflow is needed. Painting or epoxy coating is used to combat corrosion. Comparatively, mesh guards are used around machinery and fans, allowing air to pass through while preventing solid objects from entering the fan.

Bright basic wire might also be used for hangers and “S” hooks in coating processes.

Wire forming is the process of manipulating bright basic wire into complex 2D and 3D shapes. These resulting wire forms are used in places like retail, agriculture, and manufacturing and are often used to make components of larger assemblies and products. Wire forms are also used in ornamental artwork to display and create an internal supporting structure.

More specifically, bright basic wire form applications can include:

Cable management is an essential aspect of many electrical installations, though sometimes overlooked. From server rooms to control panels and distribution systems, clear, well-organized cable installation and routing simplifies servicing and maintenance work.

Bright basic wire applications here include cable trays (in the form of mesh), supports, hooks, and hangers. These may be chrome-plated or epoxy-coated for appearance and durability. Bright basic wire is also used for cable lacing, where it’s wound around a cable harness, holding the individual cables together in a specific pattern or arrangement.

Bright basic wire offers the strength and durability needed in harsh, industrial applications. It can be easily formed, bent, and cut, making it adaptable to these different applications, and it can be relatively cost-effective to purchase compared to other materials.

If you have product, storage, material handling, or construction applications that would benefit from bright basic wire, Fayette Custom Wire can help.

Founded over 50 years ago, we specialize in manufacturing steel wire products. We can draw bright basic wire in a variety of alloys and in diameters up to one inch.

Contact us today to learn more about our capabilities or to request a quote.

©2025 Fayette Custom Wire Products, LLC