Uses & Benefits of Stainless Steel Wire

This blog explores the four primary types of stainless steel wire: austenitic, ferritic, martensitic, and cold heading, and their uses and benefits.

This blog explores the four primary types of stainless steel wire: austenitic, ferritic, martensitic, and cold heading, and their uses and benefits.

Stainless steel wire, while primarily known for its corrosion resistance, is harder than wire made from regular grades of steel. It can also withstand extreme temperatures, has an attractive appearance that can eliminate the need for coating, and, in some grades, is non-magnetic.

Because of these characteristics, stainless steel wire is useful for automotive, construction, agriculture, consumer goods, and general manufacturing applications.

There are four primary forms of stainless steel wire: austenitic, ferritic, martensitic, and cold heading.

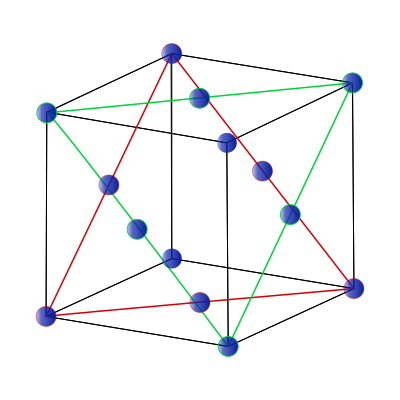

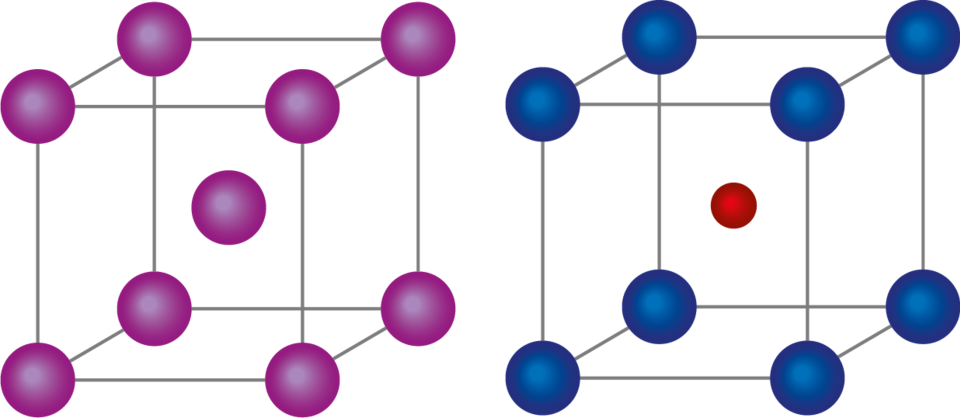

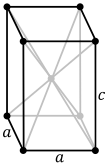

Before we break down each form, it’s important to understand that “austenitic,” “ferritic,” and “martensitic” refer to the crystal structure of stainless steel. Crystal structure could be face-centered (FCC), body-centered cubic (BCC), or body-centered tetragonal (BCT), which is a distorted form of the BCC structure caused by carbon atoms in the interstitial spaces.

Each structure influences the properties of stainless steel. For example, martensitic stainless steels (which have a BCT structure) feature chromium and medium to high carbon levels that can be heat treated to achieve high tensile strength.

“Austenitic” refers to stainless steel with a face-centered cubic (FCC) structure resulting from high levels of chromium and nickel. Austenitic grades, like 304 and 316, have excellent corrosion resistance, good ductility, and good weldability. They’re also non-magnetic and contain elevated levels of nickel that result in high-temperature resistance. The downside is that these grades work harden but cannot be hardened through heat treatment.

Austenitic stainless steel wire is ideal for use in highly corrosive environments, such as those found in food production, chemical processing, and medical device manufacturing, where sanitation requires rigorous cleaning regimens. More specifically, uses of austenitic stainless steel include wire meshes and screens, some heat exchangers, welding wire, and springs (in the automotive and agricultural sectors).

Ferritic steel contains lower proportions of chromium and nickel in a body-centered (BCC) structure. Common ferritic grades, such as the 409 series, offer good corrosion resistance and strength but have lower ductility compared to the austenitic grades. Unlike austenitic wire, ferritic grades are magnetic.

Ferritic stainless steel wire is used in a wide range of automotive, consumer products, and general industrial applications, as well as for architectural trim. Specific stainless steel wire applications include dishwasher racks and baskets, exhaust hangers, muffler components, decorative meshes, and fasteners.

Martensitic stainless steel has a BCT structure due to the elimination of nickel. This structure yields a high-strength, high-hardness alloy with excellent wear resistance and moderate corrosion resistance. Unlike austenitic and ferritic grades, martensitic stainless can be quenched and tempered to raise hardness, although this also makes it more brittle.

One of the primary application areas for martensitic stainless steel wire is making high-strength springs, particularly those used in locks. Other uses include wire brushes, high-strength fasteners, needles, and valve components.

Cold heading stainless steel wire can be either austenitic (FCC structure) or ferritic (BCC structure). It generally has slightly lower levels of carbon but higher levels of nickel. Some cold heading grades also include copper and/or manganese to enhance corrosion resistance and antibacterial properties, improve sulfur control, and promote an austenitic structure.

Cold heading quality stainless steel wire is used in products requiring significant amounts of deforming and/or forming. Specific applications include wire forms, specialized fasteners, rivets, pins, automotive fasteners, construction fasteners, and threaded rods.

Fayette manufactures and supplies a wide range of products, including stainless steel wire, bright basic wire, and wire rod. Our other capabilities include heat treating, galvanizing, cleaning, and coating.

When you work with Fayette, you’re not just working with a supplier—you’re working with a turnkey partner. Our state-of-the-art facility features an on-site quality lab, which minimizes delays associated with checking material quality. We also provide our customers with JIT delivery. We understand our customers operate in fast-paced, dynamic environments, so we’re determined to ensure they have access to the products they need, exactly when they need them.

Visit our website to learn more about our stainless steel wire product, or contact us today to learn more about our services and capabilities.

©2026 Fayette Custom Wire Products, LLC