Common Applications of Cold Heading Quality Wire

Cold heading quality (CHQ) wire is used in numerous applications due to its inherent mechanical properties. Learn more about its common uses.

Cold heading quality (CHQ) wire is used in numerous applications due to its inherent mechanical properties. Learn more about its common uses.

Cold heading quality (CHQ) wire refers to a special type of steel wire that undergoes the cold heading process. The cold heading process involves deforming metal at room temperature, which work-hardens the material through strain hardening, thus increasing the tensile strength, yield strength, and hardness of the final product.

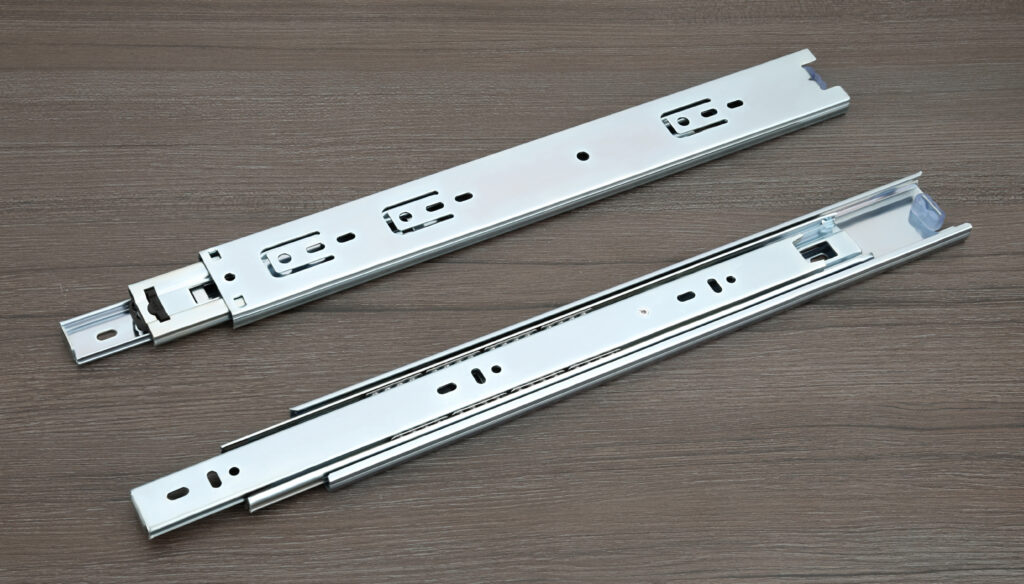

Due to CHQ wire’s inherent properties, it’s primarily used to manufacture standard and custom fasteners, drawer hardware, and structural connections that are relied upon in high-load and high-stress applications in the automotive, construction, agriculture, and consumer goods industries.

CHQ wire can be repeatedly deformed into complex shapes, so it is ideal for producing screws, bolts, nuts, rivets, studs, and other fasteners that are used in applications ranging from engines and transmissions to industrial machinery and mining equipment.

Beyond formability, other benefits of CHQ wire (when used to product fasteners) include:

CHQ wire has higher tensile strength and yield strength than hot-rolled parts, which matters greatly when producing components like drawer hardware that must experience and perform optimally under repeated stress and friction.

Additionally, the cold heading process allows tighter control over carbon content and other alloying elements, providing more predictable properties across the entire coil, which also helps to ensure consistent performance under repeated stress. CHQ’s exceptional surface finish also means that the hardware won’t have surface defects that could cause stress concentrations.

CHQ wire is also more affordable than other fabrication methods. It offers high production speeds and fewer secondary operations, making it a model material option for high-volume manufacturing.

CHQ wire delivers the consistency and strength needed to ensure safety in structural applications. It’s often used to produce complex structural connections like hex heads, socket heads, and flanged bolts. Compared to hot-rolled components, CHQ wire is less likely to crack under extremely high loads due to its uniform pearlitic or spheroidized microstructure throughout its cross-section.

Another benefit of CHQ wire (particularly in structural applications) is that it has exceptional tensile strength while maintaining relatively low weight. Because the chemical composition of CHQ wire is so tightly controlled, it also has excellent fatigue resistance under cyclic loading, which is highly needed for components that are subject to wind loads or vibration.

Founded over 50 years ago, Fayette Custom Wire is a leading, U.S.-based manufacturer of specialty steel wire and wire rod products, including cold heading quality wire. Clients in many industries, including automotive, construction, agriculture, and industrial, continually rely on us for exceptional communication, high-quality products, reliable just-in-time delivery, and other value-added capabilities, including Statistical Process Control reporting, in-house quality control, barcoding, and packaging.

Please contact us today to learn more about our capabilities or to place an order.

©2026 Fayette Custom Wire Products, LLC